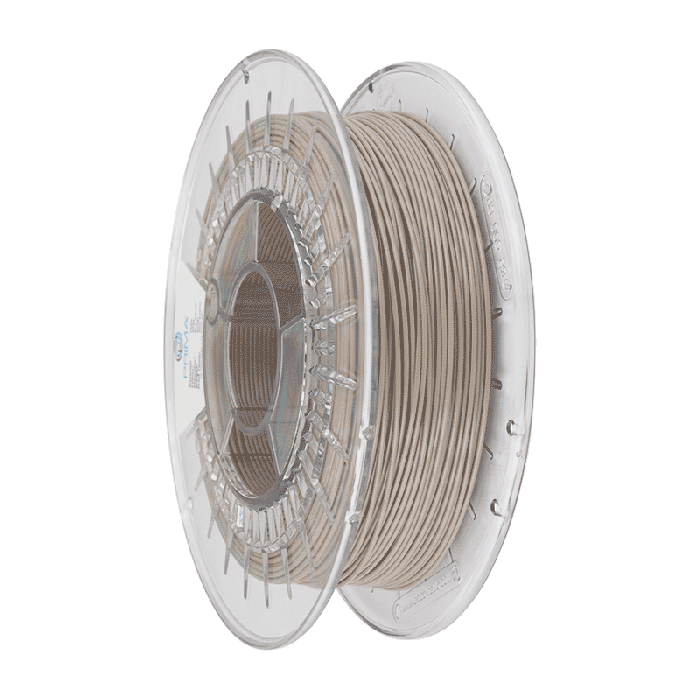

PrimaSelect Luvocom 3F PEEK 9581 - 1.75mm - 500g - Natural

PRIMACREATOREAN : 7340002117614

Mfg Part No : >PS-PEEK9581-175-0500-NA

PrimaSELECT™ Luvocom 3F 9581 PEEK (Polyether Ether Ketone) is a semicrystalline thermoplastic that is one of the most used high-performance plastics in the world. It is used to manufacture parts for the aerospace, gas, oil, medical and automotive industries.

Material properties PrimaSELECT LUVOCOM 3F PEEK 9581:Out of Stock

Description

PrimaSELECT SELECT Luvocom 3F 9581 PEEK – Buy the right PEEK 3D printer filament for your application

PrimaSELECT SELECT Luvocom 3F 9581 PEEK (Polyether Ether Ketone) is a semicrystalline thermoplastic that is one of the most used high-performance plastics in the world. 3D print strong parts for the aerospace, gas, oil, medical and automotive industries.

Material properties PrimaSELECT LUVOCOM 3F PEEK 9581:

- 3D print strong parts – Very high chemical & heat resistance

- One of the most used high-performance thermoplastics

- Replace metal components and safe manufacturing costs

- Much easier than other PEEK filaments to 3D print

- Manufacture resistant parts for the aerospace, gas, oil, medical, automotive and many more industries

PEEK 3D prints replace different polymer & metal components

PEEK is most often used to replace different polymer and metal components in cars, machines and airplanes. Thanks to a very high heat and chemical resistance PEEK can be used in many ways as metal components are usually used. It can retain its properties at high service temperatures over a long time. PEEK is also used in the medical field as it is perfect to make customized prosthetic parts such as arms, hands and cranial implants.

Easier to 3D print PEEK filament

For a long time, PEEK was one of the hardest materials to 3D print but after much research an additive was invented and the PEEK Luvocom 9581 was introduced. This new additive has changed the way PEEK can be used as it is now made to work better with FDM 3D printers.

Perfect manufacturing process ensures high PEEK filament quality

The SELECT Peek never comes in contact with water during the manufacturing process and is directly packed in vacuum sealed bags. This and the additive create a PEEK filament with excellent layer adhesion which of course greatly improves the impact resistance, durability, strength and also makes the printing process much easier than with regular PEEK.

3D printer requirements for 3D printing PEEK filament

To make a successful PEEK 3D print there are a few things to keep in mind. Your 3D printer must have the performance to meet the PEEK filament requirements. The PEEK filament should be 3D printed with a nozzle temperature of 360 - 400°C. The heat bed should be set to 120°C and a heated building chamber is important to have. Also ensure, that your 3D printer is placed in a room, where’s hardly any draft and temperature fluctuations. PEEK is best 3D printed on a PEI sheet at a printing speed of 15-30 mm/s.

Why should I use PrimaSELECT PEEK?

- New formula makes it easy to 3D print, compared with regular PEEK filament

- One of the strongest filaments on the market

- Excellent heat resistance

- Very high chemical resistance

- Can be used for a wide range of applications

Technical Data

| Basic Data | |

| Material | PEEK 9581 |

| Diameter | 1,75 mm |

| Tolerance | 0,05 mm |

| Weight | 0,50 kg |

| Length | 155 m |

| Printing Parameter | |

| Recommended Min Print Temp | 350 C |

| Recommended Max Print Temp | 380 C |

| Recommended Min Bed Temp | 120 C |

| Recommended Max Bed Temp | 160 C |

| Recommended Min Print Speed | 15 mm/s |

| Recommended Max Print Speed | 30 mm/s |

| General | |

| Specific Gravity | 1,34 g/cm3ASTM D72 |

| Mold Shrinkage | 1,0-1,6% |

| Tensile | |

| Tensile Strength | 95 MPaISO 527 |

| Tensile modulus | 3440 MPaASTM D638 |

| Elongation | |

| Elongation at yield | 5 %ISO 527 |

| Flexural | |

| Flexural Strength | 150 MPaISO 178 |

| Flexural Modulus | 2500 MPaISO 178 |

| Other | |

| Impact Strength | 7 KJ/m2ISO 1791eA |

| Spool Type / Specs | |

|  |

| 1. Prima Select 500g/750g | |

| Ds | 200 mm |

| ds | 53 mm |

| Ws | 51,5 mm |

| ws | 45 mm |

| Emty Spool Weight | 0,229 kg |

| Spool Material | PC |

| DB | 205 mm |

| WB | 62 mm |

| HB | 213 mm |

| Empty Box Weight | 0,105 kg |

| Box Material | Carboard |

Reviews

Are you sure you would like to remove this item from the shopping cart?

This item is a part of the approved quote. Removing it will remove all quote items from the cart.